What is Desizing?

Desizing is the first wet process in the textile processing of raw grey fabrics. In one word it’s the removal process of previously applied size materials (during sizing). Desizing depends on applied size materials. Desizing is done on raw greige (grey) fabric, that is means when the fabric is unprocessed or in an unfinished raw condition. The previous processes of desizing are brushing, croping, and singeing, and the next processes are scouring and bleaching the textile industry. The objective is to remove size material from the raw fabric so that dyeing and printing process can be smooth. This article is about to desizing mechanism, processes and types of desizing in Textile Industry.

What are the size materials?

Size materials are basically starch or synthetic film-forming polymers. To improve the strength and smoothness of yarn before weaving size materials are applied on yarn (warp yarn) to prevent repeated breakage with the loom. Commonly used sized materials are Starch, CMC, Guar Gum, PVA, Acrylic Polymers, etc. Tallow, Wax, Urea, Lubricants, etc also used during Sizing for auxiliary purposes.

Why do we need further removal of Size materials?

Ok, as we know, sizing is a coating with a thin polymer film on the yarn surface. Though it enhances smoothness and strength fabric stage is not the last stage of Garments processing. We are required to remove this outer layer for Dyeing and other subsequent processes.

Now if we used Starch as a size material, it can decay naturally. But in industrial practice, it’s a misfit. Because it takes a huge time and floor space but the most serious thing is outputs are unpredictable. It means uneven Desizing. If we use synthetic-size materials, then the removal process is quite easy, but synthetic agents are expensive. So, for techno-economic consideration mixer of natural and synthetic agents is used.

Desizing Processes in Textile Industry

Starch, and its chemical compositions

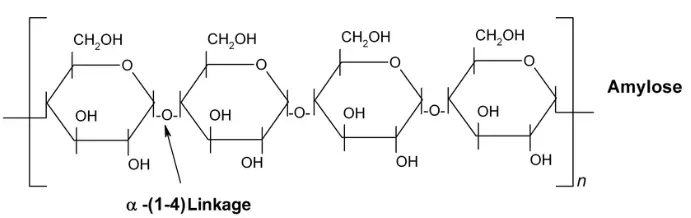

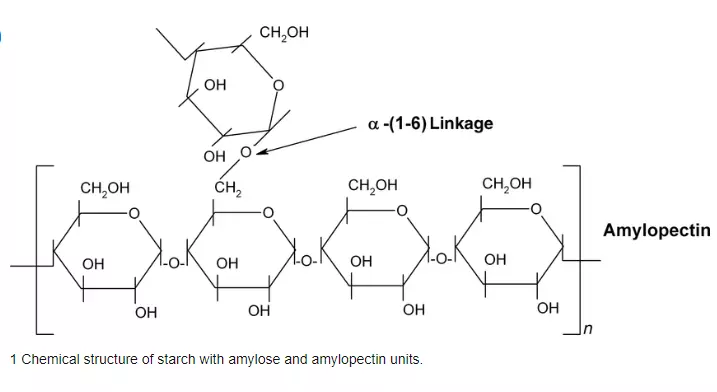

Starch contains Amylose and Amylopectin in its structure. Where Amylose in the greater portion and Amylopectin is the lower portion. Amylose is water soluble but due to the presence branch chain in Amylopectin, it is water insoluble. So, in the Desizing process, our main focus is to remove Amylopectin. Let’s consider its structure.

So, for 1-6 linkage it remains insoluble in water.

We can soluble it by breaking 1-4 linkage or by Oxidation of -OH groups present in the ring structure. In Desizing Starch convert to Dextrin, Maltose, and Glucose which are water-soluble.

Methods/ Type of Desizing

From ancient to recent Desizing are mainly four types:

- Rot Steeping

- Acid Steeping

- Enzymatical Desizing

- Oxidative Desizing

Rot Steeping

It is a very easy and old method, no specialized chemical is used. During this process, fabrics are passed through hot water without squeezing and stored covered by polythene. Microorganism generates in hot and warm conditions. And they start to degrade starch. This process is taking time generally 24 hours.

Advantages:

- No chemical use

- Minimum Cost

- Environment friendly

- Very easy Process

Disadvantages:

- Large floor space

- Huge time-consuming (24 hours)

- Uneven effect

- Industrially not suitable.

Acid Steeping

In this process, fabric passed through an acid solution mainly HCl with a concentration of 0.5-1 % according to fabric weight (owf). Then the fabric was stored at room temperature at 30℃ for a few hours. Acid break 1-4 linkages and size materials soluble into water.

Advantages:

- Cheap process

- Energy efficient

- More weight loss

Disadvantages:

- Cotton fabric degradation starts if the acid concentration is above 2% during storage.

- Time-consuming (Around 2 hours at 60℃&4 hours at 30℃)

- Large Floor Space

Enzymatic Desizing

Before this, let’s talk briefly about Enzyme. The term Enzyme is used to indicate Bio-catalyst. Enzymes are proteins with high molecular weight. They are very specific in their action. One enzyme doesn’t act on other substrates. If we changed the conditions, they remain in inactivation mode. A 10-degree Celcius increase in temperature reduces 50% of efficiency. Enzymes are named according to the substrate they act on like,

- Amylase act on Amylose

- Cellulase act on Cellulose etc.

Enzyme Sources:

- Melt, from plant origin

- Pancreatices enzyme from animal origin

- Bacteriacal enzymes are artificially made by genetic modification.

Conditions of Enzymatic Desizing:

Source pH Temperature

Malt 4.6-5.2 (50-60) ℃

Pancreatic around 7 (40-55) ℃

Becteriacal 5-7 (60-70) ℃

Typical Recipe for Enzymatic Desizing:

Bacterial Enzyme 2-5 g/l

Common Salt (Activator) 5g/l

Wetting Agent (Non-ionic) 1.5g/l

pH around 7

Temperature (70-80) ℃

Advantages:

- Environmental friendly

- Less time required

- Good desizing effect

- Do not hamper Fabric strength

Disadvantages:

- Costly

- Careful condition control

- Sometimes tough to find skilled person

Oxidative Desizing

This Desizing technique is effective on both natural and synthetic-sized materials. Oxidative Desizing agents are NaBrO2, NaOCl (Chemic), H2O2, etc. But in recent time NaOCl does not use cause, with the presence of protein impurities in Cotton fabric it generates yellow spots which are tough to remove. As oxidative agents are costly so this process is performed with scouring to meet the cost.

Conditions of Oxidative Desizing:

Persulphate 0.3-0.5 %

Temperature 100℃

Time 10 min. pH 12

During Desizing 85% of the size was removed. Rest will be removed in the subsequent next process.

Advantages:

- Fast process

- Effective on both natural and synthetic impurities

- Continuous process

Disadvantages:

- Careful control

- Costly Chemicals

- Hamper on fabric structure

- You may love to read: Application of Foam Technology in Textile Industry

- Basic Anatomy of Reactive dye

- Author: Najmul Hossain

- Lecturer, Department of Textile Engineering

- Chittagong National Engineering College, Affiliated with the University of Chittagong

- Email: [email protected] LinkedIn: Najmul Hossain