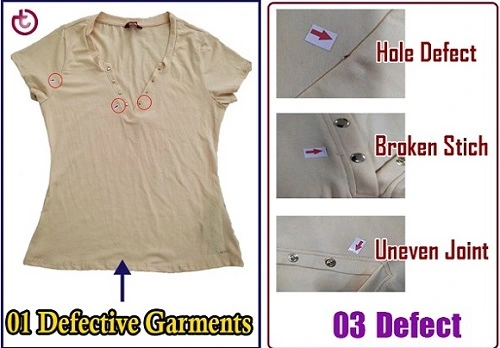

A defect is a kind of flaw. To maintain a good quality level, we need to know about defects produced in the garments industry. A common and popular word in the garments industry is a defect. Rejecting the item is another term for garment faults. The garments industry is prone to a variety of flaws because of criticality in the sewing process. These flaws in garment manufacturing depend on how they are categorized and how well an inspector can make judgment calls. It is unrealistic to compile a list of every possible flaw that could be found during a quality inspection. Despite this, the tables that follow do include information on the bulk of flaws. Here I am present on 3 defect categories and the defect list; Major, Minor, and Critical Defects in the Garments Industry.

Garments Defects Types/ Classification

According to the garments quality inspection, there are three categories of workmanship, functional, and appearance defects:

- Major Defects in the Garments Industry

- Minor Defects in the Garments Industry

- Critical Defects in the Garments Industry

Major defect

A major defect is a defect that affects the Aesthetics of the final product, the durability of the product. Due to this the garment is complained about and returned. That is, there are defects in the clothes that are noticeable. Due to this, if there is a major defect in any garment, it is returned by the customer. For example:- Some of the Major defects are Intermittent stitching, Large stitch gaps between stitches, and Problems like open seams are called major defects.

Minor defects

A minor defect is a defect that is not clearly visible to the eye. Not affecting the function, and aesthetics of the product. That is, if there is a minor defect in any garment, then there is no difficulty in buying the garment. Some examples of minor defects are explained. For example:- small uncut thread, uneven lob.

Critical defects

A critical defect is a bigger defect than the above two defects. It directly impacts product function. Generally, a critical defect renders the garments unusable. If a critical defect is found anywhere then it is better not to buy the garment. Because critical defects include various problems that render the garment unusable. Some examples of critical defects are:- Breaking something like metal and staying in clothes, No buttons in clothes, and Having problems with clothing care labels. These problems are classified as critical defects.

List of Major, Minor, and Critical Defects in the Garments Industry

| Critical Defect | Major Defect | Minor Defect |

| Insect in Garment | Skip Stitch | Uncut Thread |

| Broken Needle in Garment | Broken Stitch | Gathering or bunched stitching |

| Wet Garment | Down Stitch | Insecure shoulder tape |

| Mold in Garment | Raw Edge | Darts not properly located |

| Broken Button | Open Stitch | Uneven Lob |

| Loose Button (Kids Item) | Pleat | Broken Yarn |

| Melt Button | Puckering | Miss pick |

| Button Sharpness | Twisting | Needle mark |

| Nail Sharpness | Short Stitch | Over Stitch |

| PO Number Mistake | Barring, dye lines, and dirty marks not effected appearance | Crooked label |

| Style Number Mistake | Uneven Stitch | Wavy Stitch |

| Country Code Mistake | Uneven Join | Print missing |

| Season Number Mistake | Join Stitch | Collar Point inconsistence nose |

| Print Missing in Garment | Slanted | Minor variation in shading between garment pieces |

| Connecting Thread (Kids Item) | Print Missing | Dirt material that can easily be washed off. |

| Over Moisture | Bar tack Missing | Uneven Stitch |

| Style Mistake | Bar tack Displace | Pleat (that can be easily removed). |

| Expired Chemical use for Dyeing | Fabric Fault | Fabric bowed less than 1/4″ |

| Sharp edge | Shedding | Untrimmed thread ends 1/2″ or less than 1/2″ (inside or top side) |

| Fabric flaws (slub, knot, missing, thick yarn) less than 1/4″ | Oil Stain | Barring, dye lines, and dirty marks not effected the appearance |

| Buttons/poppers insecure, broken, missing, or poorly attached (kids) | Oil Spot | The price information on hangtag missing |

| Rusting or tarnishing of buttons/poppers | Dirty Spot | |

| Washing symbol on the care label missing | Print Bowing | |

| The price information on the hangtag missing | Uneven Stitch Density | |

| Open Seam |

Additionally, The above defect classification is factory standard but this defects classification criteria can be changed based on buyer requirements. Most garments buyer have their own defect manual on Major, Minor, and Critical Defects. But the categorization is almost similar to all.

Conclusion

Major, Minor, and Critical are 3 types of Defects in the Garments Industry. This category is made according to severities, defects places, and how the impact on the garment’s function, performance, and aesthetic view.

- Finally, You may love to read: Different Types of Defects in Garments and their Classifications

- Packaging Defects Found in Garments Industry

- Product Safety and Regularity Defects in the Garments Industry

- List of Sewing Defects found in Garments Industry

- Stitching: Sewing Defects in Garments

- Sewing Defect with Root Causes and Corrective Actions