The Martindale Pilling Test Method

In the textile industry, a piece of fabric must undergo several tests to ensure its quality and durability. The Martindale test method, also known as Martindale Abrasion cum Pilling tester for fabric, is a method that is used to determine the abrasion resistance of a given textile. I present here the Martindale Pilling Test Method of Fabric in the Textile Industry.

The Martindale is a unit, and it qualifies for the level of abrasion. The Martindale method is when a textile sample gets rubbed with a special force against a standard abrasive surface.

In this article, we will dive further into the Martindale pilling test method and other relevant topics.

What is the Martindale Test Method?

The Martindale test method is used on textile fabric to test them according to the Martindale standard system. This measures the durability and stretchability of a fabric. A layer of wool or sandpaper oscillates using a discover the fabric. The duration for the textile to start showing signs of distress is the measure of its strength.

The Martindale tester can determine the resistance ability of leather, insole, and textile. This method is also known as the Martindale pilling test, where the number of formations of fabric balls pilling on the fabric due to the entanglement of fibers is monitored. There is a procedure to follow for carrying out the Martindale test method.

Martindale Pilling Test Method

To determine the wearability of fabric, it has to go through the Martindale test method. The pilling method uses a pilling testing machine where the test specimen rubs on the mounted fabric in geometric shapes.

This also helps to identify how much fabric will form pilling when it goes under stress. To go through the process various tools are used to carry it out.

Tools Needed:

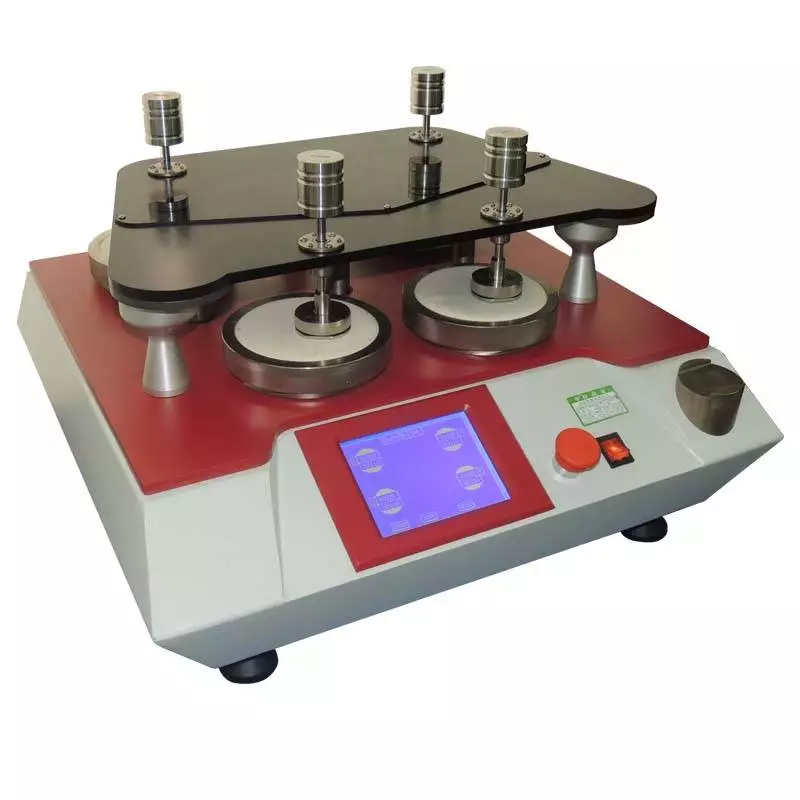

- Martindale pilling tester. This is one of the modern versions of the Martindale pilling tester.

- Scissors

- Processed or dyed fabric can also have printed. 38 mm circular diameter pieces and 140 mm small pieces are cut from the fabric.

- Marking pen

- Scale to measure

The Test Procedure:

- The 38 and 140-mm diameter pieces are placed on the machine according to size and appropriate area.

- On the electronic counter meter, 100 turns are set. This is the standard number, but it can go higher if needed.

- Switch on the machine by turning on the main power supply and then press the button on the machine.

- The machine starts automatically and stops after reaching the preset number of turns.

- The 38 mm piece is removed from the machine and compared to the standard piece. This helps to evaluate the degree of pilling.

- A series of pilling resistance can be noticed during the comparison.

- Using an arbitrary rating scale, the fabric’s resistance is rated from 1 to 5.

Why is the Martindale Test Method Needed?

The Martindale test method is crucial for textiles as it helps to identify the resistance power of fabric. The test results evaluate how much wear and tear a particular piece of fabric can endure before it starts to make noticeable changes. Most textile fabrics use this method as it makes it easier for manufacturers to know how to treat each material. If the test score is high, the fabric is more durable and does not readily form tears.

Martindale Test Scores for Upholstery

The test scores determine which fabric to use for manufacturing the material. It is not ideal to use a fabric that cannot withstand enough pressure to create a product that is used for rough uses. All manufacturers should know the score list to avoid making expensive mistakes.

Here are all the Martindale test scores and what each of them identifies.

- 10,000 or lower – A fabric with 10,000 or lower Martindale units is pretty fragile and can be used for decorative fabric such as accents or cushions. For furniture or general domestic upholstery, it is not ideal.

- 10,000 to 20,000 – These fabrics should be used to manufacture light domestic items. Suitable for fabrics that are made using delicate yarns, they should only be dry-cleaned.

- 20,000 to 25,000 – The fabric is suitable for manufacturing everyday items such as the main furniture at a house, such as sofas or chairs. However, using them for items that have to endure high-stress levels, such as recliners, is not ideal.

- 25,000 to 30,000 – The fabric is used for heavy domestic items for everyday use. Motion furniture or recliners use these fabrics as they are heavy-duty and do not form wear and tear with rough use.

- 30,000 to higher – This fabric is a commercial grade, and they are very heavy-duty. They are ideal for a commercial environment and do not wear out even after years of usage.

Final Words

The Martindale test method is an important method that helps identify how much stress a specific type of fabric can endure before it shows visual changes. This test is carried out for almost all fabrics, as the manufacturers should know about the resistance power of a material before starting to work on it. Higher Martindale scores determine that the fabric is stronger. This method is suitable according to most international standards.

- You may love to read: Textile Testing: Fiber, Yarn, Fabric, and Garments test

- Types of Garments Test in the Apparel Industry