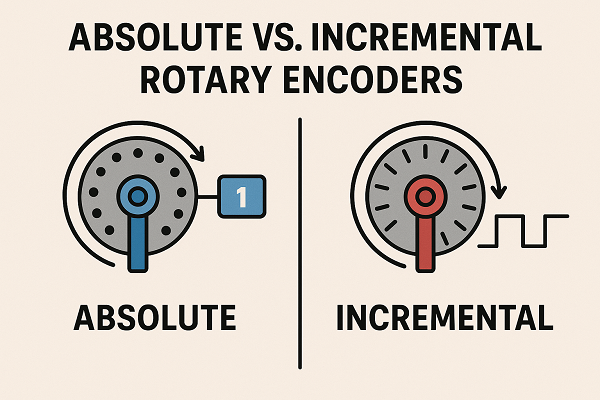

In the world of motion control and automation, encoders play a vital role in providing feedback on position, speed, and direction. Two of the most common types are absolute encoders and incremental rotary encoders. While they serve similar purposes, their methods of operation and ideal use cases differ significantly. Understanding these differences is key to selecting the right encoder for your application.

What Are Encoders?

An encoder is a sensor device that converts mechanical motion—such as rotation or linear movement—into electrical signals that can be read by a control system. This feedback allows machines to monitor and adjust performance in real time, ensuring accuracy and efficiency in processes like robotics, CNC machinery, and industrial automation.

Absolute Encoders

An absolute encoder provides a unique digital code or “position value” for every shaft position. It uses a coded disk or magnetic pattern to assign a distinct binary or Gray code value for each location. Even if power is lost, the encoder can report the exact position when power is restored, without needing a reference point.

Advantages

- True position feedback that delivers precise position information at all times, even after power interruptions.

- No homing required, eliminating the need for a reference or zeroing routine.

- Enhanced reliability, making it ideal for safety-critical applications where knowing the exact position is essential

Ideal Applications

Absolute encoders are ideal for:

- Robotics and automation systems where position accuracy is critical.

- Medical devices requiring precise, fail-safe positioning.

- Industrial machinery and assembly lines that cannot afford downtime for re-homing after a power outage

Incremental Encoders

An incremental encoder generates a series of pulses as the shaft rotates or moves. These pulses represent changes in position rather than an absolute position value. The control system counts the pulses to track relative movement. However, when power is lost, the encoder loses its reference point and must be re-homed upon restart.

Advantages

- Simple and cost-effective, typically less expensive and easier to integrate.

- High resolution, capable of delivering fine measurements of speed and distance through pulse counts.

- Fast response, making it excellent for applications where high-speed motion needs to be monitored

Ideal Applications

Incremental encoders are well suited for:

- Motor speed feedback and velocity control.

- Conveyor systems and packaging machines.

- Applications where cost-efficiency and speed feedback are more important than absolute position

Key Differences at a Glance

Absolute encoders provide exact position feedback at all times and retain position data even when power is lost. Incremental encoders measure relative movement and require re-homing after power loss. Absolute encoders typically cost more and have more complex electronics, making them the right choice for robotics, medical devices, and safety-critical automation. Incremental encoders are more affordable, simpler, and ideal for motor control, conveyor systems, and other general machinery.

Choosing the Right Encoder for Your Application

The choice between absolute and incremental encoders depends on your application’s specific needs. Choose an absolute encoder if you require continuous, fail-safe position feedback and cannot risk re-homing after a power loss. Choose an incremental encoder if you need a cost-effective solution for speed or relative movement monitoring, and occasional re-homing is acceptable.

When evaluating encoders, consider environmental factors such as dust, temperature, or vibration, along with the required resolution and budget constraints. The right encoder type will clearly align with the critical requirements of your system.

Final Thoughts

Both absolute and incremental encoders are invaluable tools in automation and motion control. By understanding their key differences, you can confidently select the right technology to ensure precision, reliability, and efficiency in your next project.