A chemical safety audit is a structured review of an organization’s chemical safety management systems, policies, and procedures. It examines the workplace in detail to identify hazards related to chemical use and evaluates how well existing safety measures are working.

These audits provide a complete assessment of potential risks and confirm compliance with regulations. With an effective chemical safety management system in place, employers can conduct audits regularly, detect and address hazards early, prevent accidents, and maintain compliance.

This guide outlines the steps for planning and carrying out a chemical safety audit in a textile or apparel facility.

Chemical Risks in the Textile Industry

The textile industry uses many different chemicals in fiber production, dyeing, printing, finishing, and garment care. These substances are essential for achieving specific colors, textures, and performance properties. However, they also present risks to worker health, workplace safety, and the environment. These risks increase if the chemicals are not managed properly.

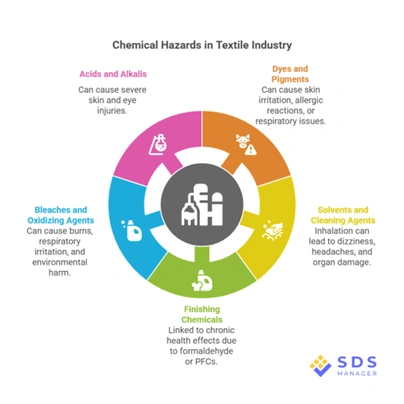

Common Types of Chemical Hazards

- Dyes and Pigments

Many synthetic dyes contain substances that can cause skin irritation, allergic reactions, or respiratory issues. Some dyes may release carcinogenic amines if improperly handled. - Solvents and Cleaning Agents

Spot removers, printing solvents, and adhesive cleaners often contain volatile organic compounds (VOCs) such as toluene or trichloroethylene. Inhalation can cause dizziness, headaches, and long-term organ damage. - Finishing Chemicals

Agents used for wrinkle resistance, stain repellence, or flame retardancy may contain formaldehyde or perfluorinated compounds (PFCs), both linked to chronic health effects. - Bleaches and Oxidizing Agents

Substances like sodium hypochlorite and hydrogen peroxide are common in textile bleaching but can cause burns, respiratory irritation, and environmental harm if spilled or misused. - Acids and Alkalis

Used in scouring and pH adjustments, strong acids (e.g., sulfuric acid) and alkalis (e.g., sodium hydroxide) can cause severe skin and eye injuries.

How Risks Affect the Workplace

Without proper controls, chemical exposure in textile facilities can result in:

- Acute effects such as burns, eye injuries, and respiratory distress.

- Chronic health impacts include skin disorders, asthma, and in some cases, cancer.

- Fire and explosion hazards when flammable liquids or powders are stored or handled incorrectly.

- Environmental contamination from spills, improper disposal, or emissions.

Understanding the Purpose of a Chemical Safety Audit

A chemical safety audit is a deep look at the entire life cycle of chemicals in your workplace. The goal is to make sure every step keeps people safe, protects the environment, and preserves company resources.

Key Goals

- Regulatory Compliance – OSHA Hazard Communication, PPE requirements, ventilation standards, and waste regulations.

- Hazard Identification – Finding unsafe conditions or practices before they cause incidents.

- Risk Control Evaluation – Testing whether existing controls (PPE, engineering controls, SOPs) are actually effective.

- Culture and Awareness – Measuring workforce understanding and safety behavior.

Guide to Conducting a Chemical Safety Audit in Textile Facilities

1) Define Scope, Team, and Schedule

- Map high-risk areas such as spot cleaning, printing/curing, washing/finishing, maintenance/boilers, chemical cages, and waste areas.

- Assign roles such as EHS lead, production rep, maintenance, HR/training, and a worker representative.

- Lock in audit dates and communicate the plan.

2) Build and Verify Chemical Inventory

- Walk through each area to list products by name, manufacturer, quantity, and location.

- Match containers to purchase records to find unlogged items.

- If an SDS is missing, use a free SDS search tool to find the most recent, compliant version.

3) Check SDS Access and Accuracy

- Ensure each hazardous chemical has a current,GHS-formatted 16-section SDS.

- Make SDSs accessible every shift. Use a digital SDS management system with QR code access to make your SDS library instantly accessible to employees.

- Mobile and offline SDS access for field or low-connectivity areas ensures workers can retrieve chemical data without internet downtime.

- Keep older versions or alternate exposure records as required.

4) Update SDSs and Labels

- Replace outdated SDSs promptly. Request from suppliers or use a safety date sheet lookup tool to speed up retrieval.

- Confirm shipped-container labels display all GHS elements: product identifier, signal word, hazard statements, pictograms, precautionary statements, and supplier info.

- For decanted/mixed containers, use a secondary container label generator to print compliant workplace labels.

5) Assess Storage, Segregation, and Quantities

- Store flammables in approved cabinets; control total volumes; keep containers closed.

- Separate incompatibles (e.g., acids from bases) per SDS Section 10.

- Bond/ground during transfers, keep aisles clear, and mark “no smoking/ignition sources.”

6) Review Ventilation, Exposure Control, and PPE

- Inspect local exhaust at spot cleaning, printing, curing, and mixing points.

- Apply the hierarchy of controls. Substitute safer chemicals, enclose/ventilate processes, then PPE.

- Conduct a documented PPE hazard assessment; verify glove compatibility, splash protection, and face/eye PPE.

- If respirators are used, maintain a written program with fit testing and medical evaluations.

7) Evaluate Emergency Readiness and Waste Handling

- Maintain a written Emergency Action Plan and Fire Prevention Plan.

- Provide eyewash/showers where corrosives are used; check weekly.

- Stage spill kits and define when staff handle incidental spills vs. evacuate for emergencies.

- Add QR code access to your SDS library at spill stations for instant hazard information.

- For hazardous waste, use closed, labeled, compatible containers under operator control, track volumes, and arrange timely disposal.

8) Training, Communication, and Follow-Up

- Train workers on labels, SDS use, area-specific hazards, PPE, and spills; refresh when new chemicals or processes are introduced.

- Post QR code access to your SDS library in chemical handling areas.

- Score audit findings with a risk assessment module to score hazards and track corrective actions.

- Assign owners and deadlines, and keep training, inspection, and incident records organized.

Chemical Safety Audit Checklist

A chemical safety audit works best when there’s a clear, structured checklist to guide the inspection. The list below covers the critical areas to review.

Download the Chemical Risk Assessment checklist for quick reference.

Chemical Safety Audit Best Practices

The below best practices ensure that the audit process is effective and that issues are resolved in a timely manner. Following a structured approach helps maintain compliance, reduce risk, and improve workplace safety over the long term.

1. Plan the Audit in Advance

Define the purpose, scope, and schedule before the audit begins. This preparation should also identify the documents and records needed. Such as the chemical inventory, SDS library, training logs, and incident reports so they can be reviewed without delay.

2. Include a Cross-Functional Team

Involve staff from Environmental Health & Safety, production, maintenance, training, and frontline operations. A range of perspectives ensures all aspects of chemical use, handling, and storage are reviewed thoroughly.

3. Confirm SDS Compliance and Accessibility

Ensure every hazardous chemical has a current, GHS-compliant 16-section SDS. Post QR code posters around work areas so that employees can retrieve safety information instantly. In facilities with low or no internet access, mobile and offline SDS access ensures compliance and safety without interruption.

4. Conduct Smaller Frequent Audits

Schedule smaller, targeted audits on a quarterly or monthly basis in high-risk areas such as printing, spot cleaning, or chemical storage rooms. These short audits can catch issues early such as missing SDSs, improper labeling, or unsafe storage and keep safety performance consistent.

5. Use Digital Tools for Faster and More Accurate Audits

An SDS management system can help track SDS currency, link each chemical to its specific work location, and issue alerts when updates are needed. This makes the audit process much easier to handle.

6. Apply Structured Risk Assessment

Use a risk assessment module to score hazards based on severity and likelihood, then address the highest-risk findings first. This approach ensures that resources are directed where they will have the most impact on safety.

7. Document and Assign Corrective Actions

Record all findings in a clear, trackable format. Assign responsibilities and completion deadlines, and follow up to ensure that each action is completed. Integration with SDS management tools can make this process faster and easier.

8. Continue Communication and Training

Share audit results with all relevant employees and provide refresher training where issues are found. Ensure workers understand chemical hazards, know how to read labels, and can access SDSs quickly.

FAQs

1. How often should a chemical safety audit be carried out in a garment factory?

At minimum, conduct a full facility audit once a year. For high-risk areas such as printing, spot cleaning, and chemical storage rooms, schedule smaller targeted audits quarterly. Frequent checks help identify issues like missing SDSs or incorrect labels before they become compliance problems.

2. What is the difference between an SDS and an MSDS?

An SDS (Safety Data Sheet) follows the GHS 16-section format, which is the current OSHA requirement. The older MSDS format is no longer compliant in the U.S., so all chemical safety documentation should be updated to SDS standards.

3. Can SDSs be stored digitally instead of in binders?

Yes. OSHA allows electronic SDS access as long as it is immediate and barrier-free. A digital chemical safety management system with QR code access and offline viewing ensures workers can find the right document instantly, even in low-connectivity areas.

4. What should be included on a secondary container label?

It should at least contain the product identifier and hazard information (words, pictures, or symbols). Using a secondary container label generator makes it easier to produce compliant labels.

5. How do I quickly replace a missing or outdated SDS?

Request an updated sheet from the supplier, or use a free SDS search tool to find the most recent version. Digital SDS management tools can sync your library automatically and flag missing documents.

- You may love to read: Technical Audit Checklist of the Garments Industry

- Technical/ QMS/ Quality Audit Checklist of Footwear Industry

- Technical Audit Checklist in Sweater Industry

- Traceability Audit in Garments Manufacturing Process