Abstract:

In this modern era, robotics is used in almost all fields. Among those fields textile industry is important all over the world because it plays a significant role in the economy. In order to survive in the competitive world market, it is necessary to adopt advanced technology. Here, robotics has emerged as a game-changer. It is a form of industrial automation. By using robots, industries can improve production efficiency and quality. This article explores the transformative impacts of robotics in the textile industry, highlighting the benefits of adopting robotics. The role of robotics in revolutionizing the traditional methods of manufacturing within the textile sector is discussed along with potential future developments in this field. The Application, Advantages, and Disadvantages of Robotics in the Textile and Apparel Industry.

Introduction:

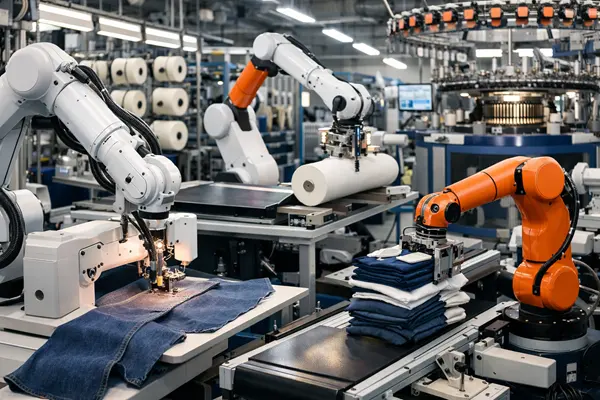

Robotics is a branch of engineering and computer science that involves the conception, design, manufacture, and operation of robots. In today’s modern textile industries, industrial robots are being used, and they’re playing a crucial role in tasks such as sewing, cutting fabric, and even sorting materials. Industrial robots are automated, programmable, and capable of movements on three or more axes, especially used for manufacturing. They’re able to perform intricate tasks easily. As technology advances, the use of robotics in the textile industry is becoming more dominant. Very soon, we’re going to witness a new era of innovation and collaboration between man and machine.

Application of Robotics in the Textile Industry:

Robotics in yarn and fabric manufacturing:

- Bale Handling: Fabrics and cotton are packaged as bales. These are very heavy and hard to move easily. Industrial robots can do this task easily. Many industrial robots are designed for weight lifting. For example: KUKA heavy-duty robots. They can also sort bales easily.

- Carding Action: A Robot could be programmed to pick up cams from each card, place them onto a truck, and transport them to a production area for a drawing frame for conventional operation.

- Splicing in autoconers and other winders: While end breaks or during bobbin change, this joins the yarn ends with a splice which is virtually identical to the yarn. The latest automatic splicer arm acts like a robot, and it offers even better opening of the yarn ends and a more favourable overlap in the splicing zone.

- Robotics in Nonwovens: The researchers are developing robots for the production of nonwoven and tailored 3D structured garments (firefighter’s suit).

- Robotics in cleaning of the textile industry: Robots with specialised cleaning tools and sensors are being used in the textile industry to clean machinery and equipment. These robots use various cleaning techniques such as brushing, spraying, etc.

Application of Robotics in Garment Manufacturing:

- Robotics in fabric spreading: Before, fabric spreading was done manually by humans. No,w with the help of an automated robot fabric spreading can be done easily.

- Robotics in laser cutting: Laser cutting is really helpful for fabric cutting. Computer-controlled laser cutting systems are suitable for multi-ply cutting of heavy textiles. It helps to increase mass production in the textile industry.

- Robotics in sewing: Sewing is one of the most challenging parts of garment manufacturing. The sewing process of 3D 3D-shaped garment is very complex. Different types of robots are being used in the sewing process. Exmp: sewing robot (sewbo), LOWRY sewbot. Sewbot is an industrial robot used in the apparel industry for fabric gripping and handling. By using these robots 100% automation to create a complete outfit is possible. And sewbots can do multiple things such as cutting, sewing, awaking, labelling, etc.

- Robotics in garments inspection: Manually performed fabric inspection can’t identify all the defects. The use of automated equipment or robots helps to increase the efficiency of the fabric inspection process. But it is one of the most difficult things to automate the inspection process. Various techniques like the statistical approach, the spectral approach, and the model-based approach can be adopted for automatic fabric inspection.

- Robotics in folding and packing: The products’ folding and packing can be carried out by robots. They can take the garment, fold it, and then pack it properly.

Advantages of Robotics in the Textile Industry:

- Increase productivity, efficiency, and quality

- Can perform tasks in hazardous situations

- No environmental comfort needed

- More accurate than humans

- Work consistently

- Fast speed

- Zero ignorance

Disadvantages of Robotics in the Textile Industry:

- Costly

- Can increase the unemployment problem

- Experts are required to maintain them

Conclusion:

Robots are changing the face of the textile industry. They are making things faster, better, and cheaper. Also, they are transforming the manufacturing process. The future of robotics in textiles looks great. There are still endless possibilities for more advancement in this sector. As there are fewer studies on robotics for textile manufacturing, the application of robots in the textile industry has not varied much from the process. By investing more in this sector and taking some necessary steps, it is possible to innovate and grow. The sooner we can introduce robotics in the textile industry, we can seek thousands of benefits.

References:

- Jindal, Harsh, and Spinder Kaur. “Robotics and Automation in Textile Industry.” Int. J. Sci. Res. Sci. Eng. Technol 8 (2021): 40-45.

- Chang, Liu. “The application of industrial robotics in the textile industry.” Industrial Engineering and Innovation Management 7, no. 1 (2024): 8-12.

- Gries, Thomas, and Volker Lutz. “Application of robotics in garment manufacturing.” In Automation in garment manufacturing, pp. 179-197. Woodhead Publishing, 2018.

Shrestha Bhowmik

Textile Engineering College, Zorarganj, Chattogram