Comparison Between CAD Marker Making and Manual Marker Making in the Garments Industry

In the garment industry, a marker refers to a thin piece of paper used for efficiently arranging pattern pieces on fabric for cutting. It’s created to minimize fabric wastage and optimize the utilization of material during the cutting process by cutting multiple layers of Fabric. Markers are essential for mass production in the garment manufacturing process. In this article, we present the Comparison Between CAD Marker Making and Manual Marker Making.

Marker making

Marker making is very essential task in industrial garment manufacturing. A marker is a thin piece of paper that is a diagram of pattern pieces. Marker making are two types; manual marker making and computerized marker making. Markers are made first before starting cutting for garment manufacturing.

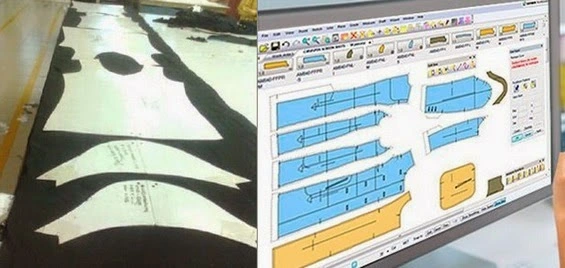

CAD Marker Making

An alternative name for computer marker making is CAD marker making. It is the most efficient marker-making system. In this system, the computer makes the marker itself according to the command given to the computer or input to the computer by a pen drive or another device.

Manual Marker Making

In the manual marker-making method, the marker man makes the marker with his hand. It is appropriate in the small-scale producing apparel industry. Manual marker-making are type: Of marker planning with full-size patterns and Markers with minimized patterns.

Comparison Between CAD Marker Making and Manual Marker Making

- In the manual system the system is used to make a maker for garment making is traditional. But in the CAD system marker making is done in a modern system.

- Marker efficiencies are not visible in a manual system. On the other hand, marker efficiency is visible in the CAD system.

- Marker length is not visible in a manual system. Marker length is visible on the monitor screen in the CAD system.

- In manual, once a marker is made, not possible to increase its efficiency. But in CAD it is possible to increase the efficiency at any time.

- Marker copying is not possible manually. In CAD, by using Plotter as much as possible copy can be done.

- Manual marker-making is a very time-consuming method whereas, CAD is a faster method.

- In a manual system, quality can not be assured. It has quality assurance.

- Manual system costing is low but CAD is expensive.

As per the above discussion, both system has some pros and cons; but CAD is the most efficient way for marker making with very lesser wastage. And mauanl is a very old and time consuming method .