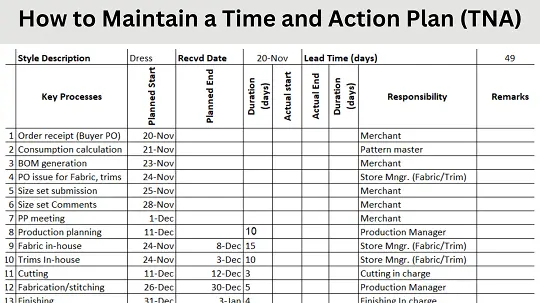

How to Maintain Time and Action Plan (TNA) in Apparel Industry

A Time and Action Plan (TNA) is crucial for smooth operations in the apparel industry. It ensures orders are delivered on time and helps manage the entire production process effectively. This is a very useful and ultimate tool for the apparel merchandiser. In this article, we discuss How to Maintain the Time and Action Plan (TNA) in the Apparel Industry.

How to Create TNA?

- Gather Information: Start by collecting details about the order, including buyer’s lead time, style complexity, fabric and trim sourcing information, and production capacity.

- List Key Processes: Identify each critical stage involved in order fulfillment, from sample development to final shipment.

- Set Target Dates: Assign realistic target dates for completing each stage. Consider buffer time for potential delays.

- Assign Responsibilities: Clearly define who is accountable for completing each task within the TNA.

Steps and Activities on How to Maintain Time & Action Plan (TNA) in the Apparel Industry

These are the key Steps and Activities to Maintain a Time & Action Plan (TNA) in the Apparel Industry

| Activities | PILOT | Bulk |

| Enquiry | 18-Nov | 30-Nov |

| Order Confirmed | 28-Nov | 10-Dec |

| COSTING | 28-Nov | 10-Dec |

| Costing Package to Vendor | ||

| Cost cnfmd from vendor | ||

| COLOR – GARMENT DYE | ||

| Color Standards to Factory | 29-Oct | 10-Nov |

| 1st lab dip to Gap | ||

| comments from Gap | ||

| 2nd lab dip to Gap | ||

| comments from Gap | ||

| All colors std due date to Brandix | 27-Dec | 27-Dec |

| SAMPLE | ||

| Product Screening | 3-Dec | 15-Dec |

| Risk Analysis Meeting | 13-Dec | 25-Dec |

| Sample Ydge | 13-Dec | 25-Dec |

| Sample Trim Order | 18-Dec | 30-Dec |

| JSS package | 27-Dec | 8-Jan |

| JSS submission | 31-Dec | 12-Jan |

| Request JSS ref Sample | 31-Dec | 12-Jan |

| JSS Commnet received | 10-Jan | 22-Jan |

| SSS rev request for JSS comments | 11-Jan | 23-Jan |

| Request Color Standard | 2-Jan | 14-Jan |

| DTM Trims ordering for green tags | 12-Jan | 24-Jan |

| Rev Medium Package | 12-Jan | 24-Jan |

| Rev Medium Submition | 14-Jan | 26-Jan |

| Request Rev Medium reference Sample | 14-Jan | 26-Jan |

| Rev Medium Commnet received | 24-Jan | 5-Feb |

| SSS rev request for RM cmts | 25-Jan | 6-Feb |

| Green tag package | 26-Jan | 7-Feb |

| Green Tag submission | 28-Jan | 9-Feb |

| Request Green tag reference sample | 14-Jan | 26-Jan |

| Green tag Comments | 7-Feb | 19-Feb |

| SSS rev request for GT comments | 8-Feb | 20-Feb |

| ISS package | 9-Feb | 21-Feb |

| ISS submission | 12-Feb | 24-Feb |

| ISS comments | 13-Feb | 25-Feb |

| SSS rev.request for ISS commnets | 13-Feb | 25-Feb |

| WASH APPROVAL | ||

| 1st submit to Gap | 6-Feb | 18-Feb |

| Comments from Gap | 13-Feb | 25-Feb |

| Wash shade band to GAP | 18-Feb | 2-Mar |

| Shade band approval | 20-Feb | 4-Mar |

| TRIMS | ||

| Sewing Trims | ||

| Color standard to BLS | 2-Jan | 14-Jan |

| Main / Japan / Joker / Europe Labels Ordered By | 7-Jan | 19-Jan |

| Main / Japan / Joker / Europe Labels Inhouse By | 22-Feb | 6-Mar |

| Care Labels Ordered By (3 days after fab test report) | 23-Jan | 4-Feb |

| Care Labels Inhouse by | 22-Feb | 6-Mar |

| Interlining Inhouse by | 22-Feb | 6-Mar |

| Zipper Ordered By (50 days from PPCD | 7-Jan | 19-Jan |

| Zippers Inhouse by (10 days from PPCD) | 16-Feb | 28-Feb |

| Button Ordered By (50 days from PPCD) | 7-Jan | 19-Jan |

| Button Inhouse By | 22-Feb | 6-Mar |

| Thread Inhouse by (10 days from PPCD) | 16-Feb | 28-Feb |

| Trim card sent for apvl | 23-Feb | 7-Mar |

| Trim Cards apvd by | 24-Feb | 8-Mar |

| AD Samples / TOP samples | ||

| Ad samples sent by | ||

| TOP spl sent | 22-Mar | 3-Apr |

| TOP spl apvd by | 26-Mar | 7-Apr |

| P.O. PROCESS | ||

| Committment issued by | 16-Jan | 16-Jan |

| P.O. Summary issued by | 19-Jan | 19-Jan |

| Packing Detail issued by (DC PO) | 10-Feb | 10-Feb |

| Check digits issued by | 10-Feb | 10-Feb |

| TESTING PROCESS | ||

| Fab submitted for testing | 13-Jan | 25-Jan |

| Fab test report due | 20-Jan | 1-Feb |

| Gmt submitted for testing | 2-Mar | 14-Mar |

| Gmt test report due | 15-Mar | 27-Mar |

| LC DETAILS | ||

| PI from Mill | 28-Dec | 9-Jan |

| Fabric L/C to Mill | 5-Jan | 17-Jan |

| Master L/C from Gap | NA | NA |

| PRODUCTION | ||

| Fabric X | 27-Jan | 8-Feb |

| Fabric in-house | 16-Feb | 28-Feb |

| cut date | 26-Feb | 10-Mar |

| Start Sew | 28-Feb | 12-Mar |

| Start dying/washing | 3-Mar | 15-Mar |

| Start packing | 5-Mar | 17-Mar |

| Final audit | 16-Apr | 16-Apr |

| Bulk Cut Date | 10-Mar | 10-Mar |

| Start Sew | 12-Mar | 12-Mar |

| Start dying/washing | 15-Mar | 15-Mar |

| Start packing | 17-Mar | 17-Mar |

| Final audit | 20-Apr | 20-Apr |

| FACTORY EX FACTORY DATE | 26-Apr | 26-Apr |

| ORIGINAL X FACTORY | ||

| EX COUNTRY | 2-May | 2-May |

By effectively maintaining a TNA, apparel companies can achieve on-time deliveries, improve efficiency, and build a reputation for reliability. By following this data list we can Maintain the Time and Action Plan (TNA) in the Apparel Industry.

- You may love to read: Importance of TNA (Time and Action Plan) in the Garments Industry