What is RFT

RFT is right the first time, a measuring parameter of Quality assurance and control like a defect, defective, DHU, and PPM. RFT is a term that tells us the first-time good rate, no need to do rework. So focusing on the right first time means focusing on the first passed. We can publish quality matrices RFT rate-wise instead of defect rate. RFT data is also reported in the textile industry. RFT target must have to be high; the more RFT is getting, the more quality is improving. RFT rate is the number of right-first-time products against 100 pcs inspection. Increasing RFT means reducing failure or defects. Here we are going to detail an example of Right First Time (RFT) for Quality control in the Garments Industry. RFT-Right First Time is part of quality metrics.

Importance of Measuring and monitoring RFT in the Garments and Textile industry

RFT (Right first time) is one of the KPIs for the garments and textile industry, especially for the garments industry. In different sections where there is inspection, RFT measuring is important. Generally, RFT-Right First Time can be measured in cutting, sewing, finishing, lot inspection, sample submission, and final inspection in a garments industry. Making the right first product will reduce cost and rework time.

How to Calculate RFT in different sections of a Garments industry

Calculation Formula: Right First Time = (Total number good products produced / Total number of inspections) * 100

For example, if 500 pcs product is produced in a Garments sewing line, found 29 pcs bad product in QC inspection then first pass quantity will be = (500-29) = 471 pcs.

So, Sewing RFT will be = (471/500*100) % = 94.20%

We can calculate RFT for other sections in the same way.

Final inspection RFT

For example, let’s imagine, if there are 150 inspections done, 7 inspections failed in the first time and so 143 inspections have passed in the first time; what will be the RFT rate for a final inspection?

So, Final inspection RFT Rate = (Total number of passed final inspections / Total number of final inspections or audits) * 100

= (143/150*100) % = 95.33%

Sample Section RFT

For example, let’s imagine, if there are 100 samples submitted to a ‘buying house’, 9 samples failed the first time, the factory had to make samples again for defective and so 91 samples have passed in the first time; what will be the RFT rate for sample section.

Sample Section RFT Rate = (Total number of first passed sample / Total number of the submitted samples) * 100

= (91/100*100) % = 91.00%

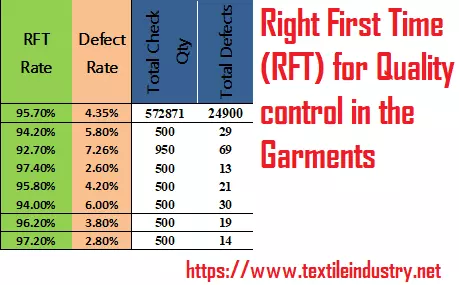

Difference between RFT and Defect

RFT-Right First Time is the opposite part of the defect. A defect is counted as the fail quantity and RFT count the pass qty. Bring in percentage will give us RFT rate and defects rate. For example, if any sewing line has 6% defect, then RFT will be 94%. Increasing RFT means reducing defects. Here I am giving a chart for understanding.

| RFT Rate | Defect Rate | Total Check Qty | Total Defects | |

| 95.70% | 4.35% | 572871 | 24900 | |

| 94.20% | 5.80% | 500 | 29 | |

| 92.70% | 7.26% | 950 | 69 | |

| 97.40% | 2.60% | 500 | 13 | |

| 95.80% | 4.20% | 500 | 21 | |

| 94.00% | 6.00% | 500 | 30 | |

| 96.20% | 3.80% | 500 | 19 | |

| 97.20% | 2.80% | 500 | 14 |

Hope this chart makes us clear to know about the difference between the defect rate and RFT rate.

Different sections where we can measure RFT in a Garments industry

- Cutting inspection RFT rate

- Sewing inspection RFT Rate

- Finishing inspection RFT Rate

- Final inspection RFT Rate

- Sample section RFT

- RFT (Right first time) in Dyeing

- Different manufacturing sections of textile industries.