How to do Quick changeover( QCO) in Garments Manufacturing

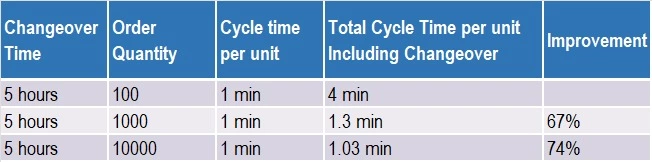

Cost stabilization depends on the proper utilization of every resource in the garments manufacturing industry, henceforth being competitive to sustain the market share and cope with the newest competitors, it is necessary to deliver quality products in time at a reasonable price to the customer.Poor resource utilization affects every aspect of production as well as[…]