Boning for Dressmaking: Types, Uses and Sewing Technique

Different ingredients have been used for dress-making. Boning is one of them. A long, flat piece of metal or plastic called “boning” is used in dressmaking to provide types of clothing items like corsets, dress bodices, bathing suits, and other items of clothing structure and stiffness. Additionally, it can be utilized to give necklines, pleats, and collar rigidity. Boning comes in different widths and is encased inside channels that are sewed into interlining. It is employed to maintain the garment’s erect appearance, harden the cloth, and give vertical support. There are several kinds of boning, including Rigilene, plastic boning, and substitutes like bamboo or wooden bits. In order to give an item of clothing a defined structure, boning is often placed into it. Examples of this include evening wear, bridal gowns, bras, corsets, petticoats, hats, swimsuits, bags, and purses. In this article, I present different types of Boning for Dressmaking, their uses, and sewing techniques.

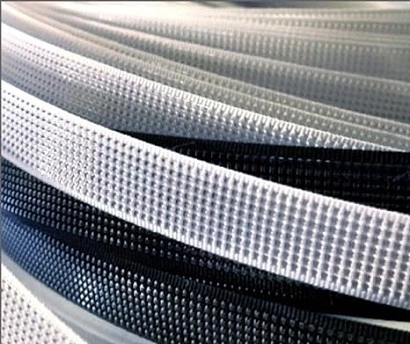

Types of Boning for Dressmaking

There are many types of boning used in various parts of a dress and also it varies from fabric to fabric. They are:

- Plastic Boning

- Steel boning

- Spiral boning

- Flat boning

- Feather boning

- Rigilene boning

Details of different types of Boning for Dressmaking, their Uses, and Sewing Techniques

1. Plastic boning

Since plastic boning is so inexpensive and versatile, it is frequently used in dressmaking and clothing manufacturing. Plastic boning, made of sturdy plastic that is frequently polyester or polypropylene, gives dresses, corsets, and bodices shape and support. Its appeal is a result of the harmony it creates between stability and flexibility. Let’s check out its pros and cons:

Advantages:

- Lightweight: It is thin and appropriate for clothing that needs a light amount of support without gaining a lot of weight or thickness.

- Cost-effectiveness: Because plastic boning is so affordable, it’s a great option for projects with tight budgets and a dependable way to achieve structure without sacrificing quality.

- Flexibility: Its intrinsic flexibility ensures the wearer’s comfort by permitting effortless movement and suppleness.

Disadvantages

- Restricted Rigidity: Although plastic boning is flexible, it cannot be as firm as what is needed for particular clothing. Other options such as steel boning more appropriate when a great degree of support is required.

- Issues with Durability: Plastic boning is susceptible to deterioration over time, particularly if it is bent or compressed frequently. Its capacity to sustain is reduced as a result, and replacement is necessary.

- Heat Sensitivity: Plastic boning susceptible to heat sensitivity. It could deform or lose its shape if exposed to too much heat. This is a crucial factor to take into account when maintaining and caring for clothing.

Uses of Plastic Boning

In essence, plastic boning is utilized to give upper wear a precise shape. Most significantly in

- corsets: When making corsets, plastic boning is frequently used. Its adaptability makes it pleasant to wear while offering the support and shaping required to keep the corset’s structure intact.

- Bodices: Plastic boning is judiciously used in fitted bodices to improve the shape of the garment. It keeps the bodice’s distinct form and helps keep the fabric from collapsing.

- Dresses: A variety of dress styles, particularly those with fitted bodices, include plastic boning. Plastic boning offers structural support without sacrificing comfort, whether it is used in evening gowns, wedding gowns, or casual attire.

- Tops without straps: Plastic boning helps guarantee that off-the-shoulder and strapless tops stay in place on the wearer’s body. The boning keeps the desired form of the neckline and helps avoid slippage.

Sewing techniques of plastic boning

In order to avoid discomfort, make sure the plastic boning is slightly shorter than the casing when measuring and cutting it to the appropriate length before sewing it into a garment. To stop the ends from fraying, you can choose to seal them with a hot knife or lighter. Make casings or channels inside the garment, indicating on the inside where each piece of boning begins and ends. Securing the ends within the case to keep them from moving, carefully slip the plastic boning into the casings. Using backstitching for strength at the start and finish, stitch a straight stitch at the edge all the way around the casing. To improve comfort and give the boning channels a more refined appearance, you might choose to line them.

2. Steel Boning

The invention of steel boning, a vital component of corsetry, transformed the way clothing is made. Steel boning is a valuable tool for precisely constructing forms and is primarily used in shape wears. There are some disadvantages and advantages to it too:

Advantages

- Enhanced Support: Steel boning is popular for shaping undergarments because it offers more support than traditional materials like whalebone or synthetic substitutes. This is wonderful for improving posture and reducing back pain.

- Durability: Steel boning has a reputation for being long-lasting and robust. Its structural integrity is sustained throughout time by its ability to endure repetitive bending and pressure.

- Effective Waist Reduction: Achieving a noticeable waist reduction in corsets requires steel boning. Because of its robust construction, it can be tied tightly without losing shape, which lowers the measurement of the waist.

Disadvantages

- Rigidity: Although steel boning offers great support, some users find it uncomfortable due to its rigidity. The material is too stiff to move freely, which makes it less appropriate for daily use or prolonged usage.

- Weight: Those looking for lighter and more comfortable choices find that steel boning adds weight to the garment.

- Cost: The price of steel boning more than that of other materials, which affect the total cost of the clothing.

Uses of Steel boning

Steel boning is frequently used to add structure, shaping, and support to a variety of dresses and clothing items. The following are some outfit types and methods where steel boning is commonly utilized:

- Corsets: A key element of corsets is steel boning, which supports and shapes the torso. Steel boning is usually sewn into the corset fabric’s channels. To preserve the garment’s structure and keep it from collapsing, the boning runs vertically. Spiral steel boning is utilized in certain designs to provide flexibility without sacrificing structural integrity.

- Bustier: Steel boning is frequently used in bustier to improve bust support and define the silhouette. Steel boning is positioned thoughtfully along the bustier’s framework to support the bust and preserve the garment’s form.

- Wedding gowns and ball gowns: Steel boning is often used in formal gowns, particularly those with fitted bodices, to provide a structured and refined look. Steel boning is integrated

- into the bodice’s seams or constructed into a structure akin to a corset underneath the dress. This aids in defining the waistline, supporting the bust, and sculpting the upper body.

- Trumpet or mermaid dresses: Steel boning is frequently used in fitted dresses—such as the trumpet or mermaid silhouettes to preserve the structure and form of the garment. To make sure the dress fits the body’s curves while offering support, steel boning can be positioned thoughtfully throughout the seams, especially in the bodice and through the hip area.

- Vintage Appearances: Steel boning is commonly used in period costumes, such as those from the Victorian era, to create the characteristic outlines of the era. Steel boning is used to precisely duplicate the intended shapes and styles in bodices, corsets, and other structural components of historical costumes.

Sewing technique of steel boning

There are various varieties of steel boning, including spiral and flat steel boning, which provide varying degrees of flexibility and support.

The dimensions of steel boning vary; flat steel boning is available in a range of thicknesses and widths from 2 mm to 20 mm, while spiral steel boning is available in a range of widths from 4 mm to 15 mm. The amount of support needed for a given project determines the type of boning to use. For example, corsets can be bonked at locations where minimal flex is needed using narrow but heavy gauge steel of about 6mm, whereas projects requiring a sleek silhouette can benefit from spiral steel boning.

3. Spiral boning

A vital element in dressmaking, spiral boning gives clothing strength and structure—especially in corsets and bodices. Spiral boning is composed of coiled metal, which gives it more flexibility and mobility than flat steel boning. Its applicability, however, is dependent on the particular needs of the garment, and designers have to balance these advantages against possible disadvantages like decreased durability and stiffness. Let’s sum it up:

Advantages:

- Flexibility: The spiral construction increases flexibility, which is perfect for clothing that needs to be comfortable and allow for mobility. This is especially useful for gowns worn for formal events where the wearer has to look put together but yet feel comfortable.

- Conforming Fit: Spiral boning gives a more customized and attractive fit by developing a smooth contour to the body. This is particularly crucial for clothing that accentuates the overall appearance, such as evening or bridal gowns.

- Breathability: Spiral boning offers superior breathability over certain rigid boning choices. This is crucial because it lowers the chance of overheating and helps control body temperature, which prevents discomfort during prolonged wear.

Disadvantages:

- Less Rigidity: Although spiral boning’s flexibility is a benefit, there are circumstances in which it is a drawback. Even with spiral boning, garments that need a lot of structure and rigidity can not get the right amount of support.

- Durability: Compared to certain more robust choices, spiral boning is more prone to bending or warping over time. When it comes to clothing that is frequently under stress or tension, this can be an issue.

- Expensive: Spiral boning could occasionally be more costly than substitutes. This have an effect on the whole cost of dressmaking, particularly for designers on a tight budget.

Uses of spiral boning

Wedding Gowns: Spiral boning, which gives bodices rigidity, is frequently used in wedding gowns to improve the silhouette of the garment.

- Ball gowns: To define the waist and keep the gown’s shape, spiral boning can be added to the bodice of ball gowns.

- Prom dresses: In fitted or strapless shapes, notably, spiral boning is employed to give prom dresses structure and stability.

- Dance Costumes: Spiral boning is frequently used in dresses for dance performances to help them keep their shape and remain in place during movement.

- Formal Evening Gowns: Spiral boning is a feature that helps create a refined and well-fitting appearance in a variety of formal dresses.

Sewing techniques of spiral boning

Spiral boning sizes vary depending on the use, but in general, the boning should be 1-1.5 cm shorter than the casing to allow for stitching across the top and bottom opening of the casing to secure the boning in place. Spiral steel boning is available in a range of thicknesses and widths, from 4 to 15 mm, so it used for projects requiring varying degrees of support. To guarantee precise dimensions and a clean cut, it’s crucial to cut the boning with the right instruments, including wire cutters. Spiral boning is an all-around adaptable method that gives clothing strength and pliability, particularly in curved body parts.

4. Flat boning

In dressmaking, flat boning is a method used to give garments like corsets and dress bodices structure and shape. To keep the fabric rigid and in shape, long, flat bits of steel or plastic are inserted within the clothing. There are several materials that can be used to make flat boning, including plastic, resin-coated steel, and spring steel.

Advantages

- Support: It helps preserve the shape and form of clothing by giving it structure and support, especially in corsetry and couture clothing.

- Versatility: Depending on the project, flat boning can provide varying degrees of support because it comes in a variety of materials, including plastic, spring steel, and resin-coated steel.

- Easy for sewing machine: Flat boning is suitable for sewing machines because it has soft edges that facilitate hand or machine sewing. It is robust, flexible, and uncracking. Moreover, flat boning is readily maintained and washable.

Disadvantages

- Restricted support: Because flat boning offers minimal support, it is not appropriate for clothing that needs a lot of shaping or support, like corsets that shrink the waist.

- The challenge in curved channels: Because flat boning cannot be stitched into curved channels, its use in some clothing designs is restricted.

- Possibility of buckling or twisting: The appearance and comfort of the garment are impacted if flat boning buckles or twists inside the casing.

Uses of Flat Boning for Dressmaking

- Evening Wear: Flat boning is frequently used in dresses for formal events to offer a well-defined silhouette and support the bodice, which helps the garment keep its shape.

- Wedding Gowns: Wedding dresses use flat boning to support and shape the bodice, resulting in a beautiful fit and preservation of the garment’s structure.

- Swimwear: To produce a snug and well-fitting garment, flat boning is used to offer structure and support, especially in the bodice area.

- Petticoats, Hats, and Purses: To give these accessories some rigidity and structure, flat boning can also be utilized in petticoats, hats, and purses.

Sewing technique of flat boning for Dressmaking

To guarantee a good fit inside the garment when utilizing flat boning, it’s critical to measure and cut the boning precisely. To keep the boning in place, it should be slightly shorter than the casing to allow for stitching across the top and bottom openings of the casing. For instance, cut the boning approximately 1-1.5 cm shorter if you are using a case that is 1-1.5 cm broad. It is important to use the right instruments, such as wire cutters, to guarantee precise measurements and a clean cut. In order to include flat boning into a garment, it is usually sewn into channels called casings that are sewn into the interlining of the garment. The casings can be constructed from a different material, like duck canvas, or from the same fabric as the lining. In order to accommodate curved seams and allow for stretching, casings should be cut on the bias. To secure the boning in place after it has been placed into the casings, the casing apertures are sewn across.

5. Feather boning

In dressmaking, feather boning, also referred to as featherlike boning, is a sort of boning that gives clothing structure and support, especially for strapless dresses, bustiers and swimsuits. Plastic feather boning is 1/4″ in diameter and has a poly/cotton covering on top. It is simple to sew by hand or by machine, lightweight, and flexible. Feather boning can be bought by the yard or in rolls. It comes in widths ranging from 1/4″ to 3/8″.

Advantages

- Flexibility: Compared to conventional steel boning, feather boning is more flexible, facilitating easier mobility and increased comfort.

- Lightweight: Feather boning is a lightweight option that works well for lightweight clothing that calls for a more subdued level of support.

- Simple to Sew: It’s a handy choice for last-minute changes or do-it-yourself projects because it’s simple to sew into clothes.

- Versatility: Feather boning is adaptable and works well with a variety of clothing items, such as costumes and lingerie.

Disadvantages

- Restricted Support: Compared to steel boning, feather boning offers less structural support, which makes it less appropriate for clothing that needs strong shaping or support.

- Durability: Over time, feather boning deteriorates and not be as strong as steel boning, especially in high-stress locations.

- Not Suitable for Thick Fabrics: Feather boning might not provide sufficient support for thick fabric clothing, which could result in poor shape.

Uses of Feather Boning

- Shaping neckline: Supporting and giving stability to a garment’s bodice, particularly in gowns with low necklines or strapless styles.

- Waist Cinching: Improving the silhouette by adding feather boning to the seams to define the waist.

- Preventing Rolling: Using feather boning to reinforce seams, you can stop a garment’s edges from rolling or folding.

- Bust Support: Providing extra support to the bust region to guarantee a snug and attractive fit.

- Flexible Movement: Suitable for clothing with more flowing designs, it permits more comfortable movement than hard boning.

- Lightweight design: most suited for softer textiles, it preserves the garment’s feeling of lightness while still offering rigidity.

Sewing technique of Feather boning

Feather boning is usually used in clothes by sewing it into channels called casings that are sewed into the interlining. The casings can be constructed from a different material, like duck canvas, or from the same fabric as the lining. To secure the boning in place after it has been placed into the casings, the casing apertures are sewn across.

6. Rigilene boning

A flexible and simple-to-use material for dressmaking, costumes, and craft projects is rigid boning. Because it is constructed from polyester that has been braided around tiny plastic rods, it is strong, flexible, and lightweight. There are many lengths of rigid boning, including 1/4″ (6mm) and 1/2″ (13mm). It is readily cut with ordinary scissors and sewn through both by hand and by machine. Advantages of Rigilene Boning:

- Flexibility: Rigilene boning is renowned for its adaptability, which enables clothing to comfortably fit the contours of the body.

- Lightweight: Rigilene boning gives rigidity without significantly increasing the bulk or weight of the garment because it is comparatively light.

- Affordability: Rigilene is frequently less expensive than some other kinds of boning materials, which makes it a wise choice for applications with tight budgets.

- Simple to Cut and Sew: Both novice and seasoned seamstresses effortlessly cut rigid netting to the appropriate length and stitch it into clothing.

Disadvantages of Rigilene Boning:

- Limited Rigidity: Although Rigilene is flexible, it does not have the rigidity needed for some projects or clothes that need a lot of support and shaping.

- Not Suitable for Heavy Fabrics: More stiff boning materials would be preferred for heavy fabrics or structured clothing, as Rigilene might not be able to support them adequately. Rigilene boning has the potential to distort or lose its shape over time if used excessively, particularly in clothing that is subjected to a lot of movement or stress.

- Visible seam lines: Thicker textiles make the Rigilene boning seams visible, which could detract from the garment’s overall appearance.

Uses of Rigilene boning

- Dress bodices: They can be used to support and preserve the shape of the garment.

- dresses without straps: Strapless dresses use rigid boning to give them a little shape and support.Bustiers: To give support and structure, bustiers employ rigid boning.

- Swimwear: It is used to offer support and structure to swimwear, especially in the bodice area.

Sewing technique of Rigilene boning

Rigilene boning to be sewn To avoid an ugly bulge, cut the boning so that it finishes about 6mm away from the top and lower seams. Stitch on the very edge of the boning, evenly distributing each side of the flat seam allowance (you should have already ironed this open and flat). Continue sewing through the lining and the seam allowance. If the boning is fraying the garment, place cotton or wadded end caps at each end. To smooth the chopped edges, you can alternatively melt them with a match, but this gets messy. Sew straight onto the material: It is possible to sew rigid boning straight to the fabric, however, this is not a popular technique. It is best when sewn flat and not into a curved seam. Finish the ends: Before sewing the Rigilene boning into your garment, finish the ends by heating them with a match or lighter to melt the rigid interior strands and prevent them from poking out. Alternatively, you can cover the cut end with a piece of fabric stitched over the end.

Though there are different kinds of boning in dressmaking all of them have some pros and cons. The sewing techniques are also different. You should choose which one is best for your dress.

Conclusion

In conclusion, boning for Dressmaking is a versatile tool in dressmaking that offers support, structure, and shape to garments. Understanding the types of boning available, their uses, and employing proper sewing techniques are crucial for achieving professional and well-fitted results in dressmaking projects. With practice and attention to detail, mastering the art of boning can elevate the quality and appearance of your garments significantly.

- Additionally, You would love to read: How to Sew Hem Your Garments with a Sewing Machine

- 12 Steps to Put and Replace Needle in a Sewing Machine