C-TPAT stands for Customs-Trade Partnership Against Terrorism, USA has taken an initiative in the Customs-Trade Partnership against Terrorism, which we call CTPAT in shortcut. In the garments industry, CTPAT will protect finished goods till dispatched from the exporting factory to keep a good supply chain. In order to get supply chain security, C-TPAT started. Here is all about C-TPAT Requirements and Procedure in the Garments Industry.

We understand the USA did C-TPAT for receiving goods error-free, a system that protects the supply chain from Terrorism so that nothing is not stealing from the delivery. Suppose we are shipping 50,000 pieces of garments to the USA, but 10 pcs were stolen from a carton and 100 pcs are stolen from the transit. So the C-TPAT is there to protect goods, in order to secure the supply chain system. So C-TPAT Requirements and Procedure has made for a good supply chain system. Here we are discussing on how to implement it in the garments industry.

C-TPAT Requirements and Procedure in details of Garments Industry

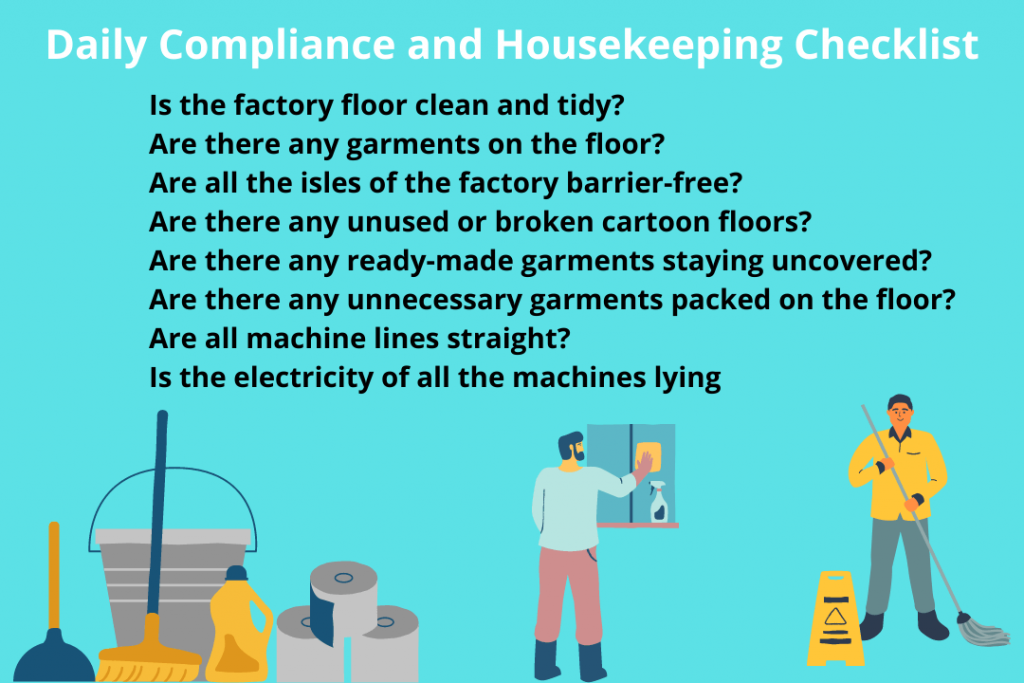

Here we are given some practices that garments follow in order to maintain the C-TPAT procedure.

1. C-TPAT requirements for ID Card and employee identifications

- • When entering the factory, the ID card must be hung around the neck. No one will be allowed to enter the factory without the ID card hanging around the neck. However, if someone cannot bring the card for any reason, then he must enter his name in the timekeeping branch.

- • If the ID card is lost, damaged, burnt, or stolen, first report verbally/in writing to the Welfare and Human Resources Department.

- • ID card must be punched at the time of entering the factory and at the time of leaving duty. It should be remembered that if one does not punch the card at the time of entering the duty and at the time of leaving the duty, his attendance may be a problem.

- • Human resource department/welfare officer after coming to know about the incident of loss, destruction, theft, and burning will take information from the worker about the incident.

- • After verifying the information, the Human Resource Department and Welfare Department will distribute the new ID card with the new ID number, excluding the old ID number.

- • Will issue a new card after depositing the lost ID card.

- • Register will save the save.

- • The ID card of departing employees should be returned to the concerned branch.

- • Since it is an electronic ID card, if it is lost or damaged, an immediate application should be made to the HR department with a penalty of Tk.

- • Loss of ID card Notification of loss of ID card should be given in newspapers.

- • Notification of loss of ID card should be published in regional newspapers.

- • GD (General Diary) should be done in case of a lost ID card.

- • Care must be taken while punching that under no circumstances the card is punched 02 (two) times.

- • If any problem occurs while punching the card then inform the HR department immediately.

- One’s card cannot be punched by another.

- • The ID card must be worn around the neck while on duty in the factory and must be kept visible from a distance.

- • No fee to pay for an ID card.

- • If anyone violates the above rules then legal disciplinary action must be taken against him.

2. Access Controls (Entryway and Inside/Outside Security Instructions):

- a) Worker/Employee, Visitor, Customer, to know identity, name, and subject during entry.

- will be In the factory, the visitor card can be written in the log book and sent inside. In the case of workers/employees, ou that must be shown.

- b) Blocking and identifying the entry of unknown and unauthorized persons in the parking area, and loading/unloading area.

- c) Money, goods, parcels arrival/departure checking, and records collection.

3. Physical Security (Own safety):

- a) Adequate locks shall be provided on all doors. Take care of factory building construction damage debris, pieces, broken windows, broken doors, and locks.

- b) Checking indoor/outdoor and stair lights.

- c) Checking the wheels/all sides of the vehicle.

- d) Check after warehouse and cover.

- e) Checking the room of chemical products.

4. Procedural Controls (Systemic security):-

- a) Policy on how records should be kept of any goods coming/going inside the factory in this system.

- b) Security guard will keep cargo entry/exit records, check shipping mark container, seal, weight vehicle driver name, etc.

- c) Inform the authorities immediately if any illegal or suspicious thing is found.

5. Personal Security (Security of Personal Information):-

- a) During the recruitment of our factory workers or employees past identity and biodata are checked.

- b) If anyone is proven to be a terrorist or a wrongdoer, he is excluded.

- c) All kinds of searches are made for suitable persons as per factory rules.

- d) Personal file of the employee is maintained with assurance after an appointment and all rules are communicated.

6. Container / Cover Van/ Truck Security (Safety of cover vans and trucks)

- a) The main purpose and aspect of this policy are to take security measures for its authenticity or danger-free location from physical presence.

- b) Security Guard / Security in charge must check the seal of a cover van.

- c) At the time of shipment of goods, 10 hours: Checks will be completed and records will be kept.

- d) Check the cover van doors/locks.

- e) Check the location of the cover van and truck and inform the authorities.

7. Security Training/ Education & Training Awareness (Safety, Education, and Training System)

- a) It is a factory education training instruction.

- b) Training on various subjects is given at least 1 time per month in our factory. Like general policies, and cleanliness.

- c) Safety precautions and other safety principles are taught.

- d) Training on fire drills by an experienced person and first aid by an experienced doctor/nurse.

- e) Besides, various aspects of the workers are highlighted in the workers/officers coordination committee meeting.

8. IT- Information Technology Security (Technological Security)

- a) The person designated by the Authority shall supervise the matter.

- b) Keep various factory data back-ups.

- c) Change the computer password after 1 month and inform the authorities.

- d) Always be aware of and prevent the factory’s own policies or data from being leaked in any way.

- e) Set antivirus to keep data, and programs safe, so that they are not destroyed.

You may love to read: Best Practices in Apparel Industry

Hope this article has given you some idea about C-TPAT Requirements and Procedure; if you have any input please write in the comment box.