Application of Industrial Engineering on Cargo Pant Sewing: Before and after IE

Industrial Engineering (IE) optimizes available resources. So the application of industrial engineering is the reduction of SMV, manpower, and Process. The application of IE increases the profit of the garments industry proved in a feasibility study. Here you can see cargo pants sewing details before and after the IE application. Hope this article would help you.

Cargo Pant

Cargo pants are characterized by cargo pockets. Typically cargo pants are expandable loose casual wear pants. These are large pockets on both (right and left) upper legs of the pants. They’re placed on the outer thighs, above the knees. Cargo pockets are typically made to be expandable, so they get bigger as more items are put inside them, and have flap closures with velcro hook and loop. The flaps may be secured with Velcro, and buttons or even magnets are sewn into the cloth. The large cargo pockets are rarely the only pockets in cargo pant styles. Usually, cargo pants have a minimum of four to six pockets and sometimes more. That includes standard back pockets and hip pockets that are found in many pant styles. Standard cargo pant designs are made to be somewhat loose-fitting and comfortable. Traditional cargo pants are used as outerwear, made in khaki, navy blue, or camouflage designs, as an homage to their military roots. However, cargo pants have evolved and changed a great deal since those early military days.

The manufacturing process of Cargo pants (without IE development)

| SL N | Case Factor | SMV | Worker | Salary | Machine/Attachment | Comment |

| 1 | Without proper use of attachment | 0.05 | 1 | 90$ | S/N needle and lock/chain stitch | Without a whipper, the operator uses his hand and takes 2 or more seconds extra. |

| 2 | Loop making and join | 0.39 | 2 | 180$ | Flatlock m/c, S/NLS | One operator makes a loop and another one operator attach the loop. |

| 3 | Flap making | 0.23 | 1 | 90$ | Single needle lock stitch | One operator use his hand for turning flap and S/NLS for attachment. |

| Total | 0.67 | 4 | 360$ |

The manufacturing process of Cargo pants (after IE development)

| SL N | Case Factor | SMV | Worker | Salary | Machine/Attachment | Comment |

| 1 | Proper uses of attachment | 0.03 | 1 | 90$ | Whipper use in S/N needle lock/chain stitch | By using whipper we can reduce time and cost. |

| 2 | Auto Loop setter | 0.28 | 1 | 110$ | Auto loop setter m/c. | Only one operator can run auto loop setter m/thus we can save time and money. |

| 3 | Auto Flap making | 0.19 | 1 | 90$ | Auto flap maker. | Auto flap making m/c can reduce time and cost. It also increases productivity. |

| Total | 0.50 | 3 | 290$ |

Result & Discussion: Before and after IE Application

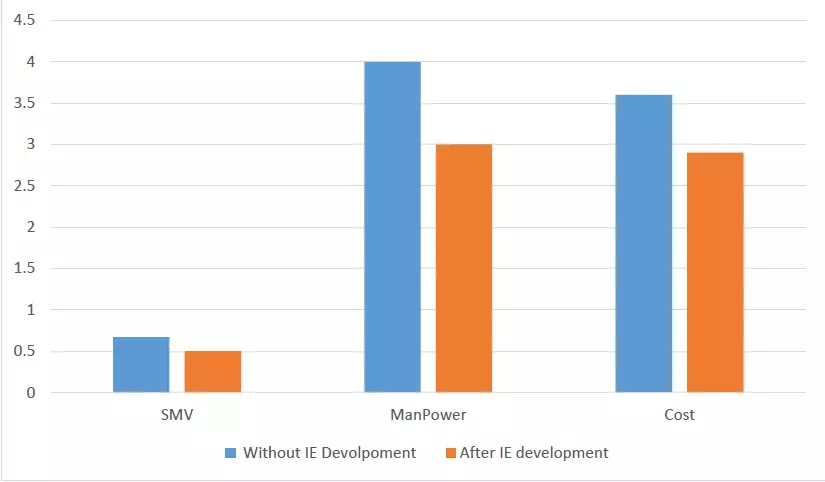

After comparing two different made of systems of Cargo pants, it can be observed. Planning and IE departments play a very vital role in this manufacturing process. IE department constantly works hard for improving process development and using advanced sewing machines for better productivity. The main purpose of the IE department is to increase efficiency decrease wastage of material and time and reduce cost. In addition, to advancing sewing machines the IE department adopts many other methods to increase efficiency and productivity which is help to reduce the cost of garment manufacturing.

In comparison between the two tables, we can see the difference, without IE development those crucial operations are without proper use of attachment, Loop making and join, and Flap making. The total SMV is 0.67, the total number of workers is four and their wages are 360$. The cost of performing those operations is not low. Here 4 operators were using 3 sewing machines (Flat lock m/c, S/NLS) those machines are increasing the power consumption. It was also increasing the cost making. It will possible to improve those processes by using Industrial Engineering techniques and tools.

After applying IE, we can see the diversity of results. After adding advanced machines to the sewing line, the number of workers has been reduced from four to three and their wages have become 290$. Now if we look at the table, we can see the total savings. Here SMV 0.17, workers 1 and their wages 40$ which is decreased due to IE. This is economical savings. Not only that, it is replacing semi-automatic machines with high-tech sewing machines which reduce energy consumption and the number of sewing machines. This reduces the cost of production, wastage of materials, and time.